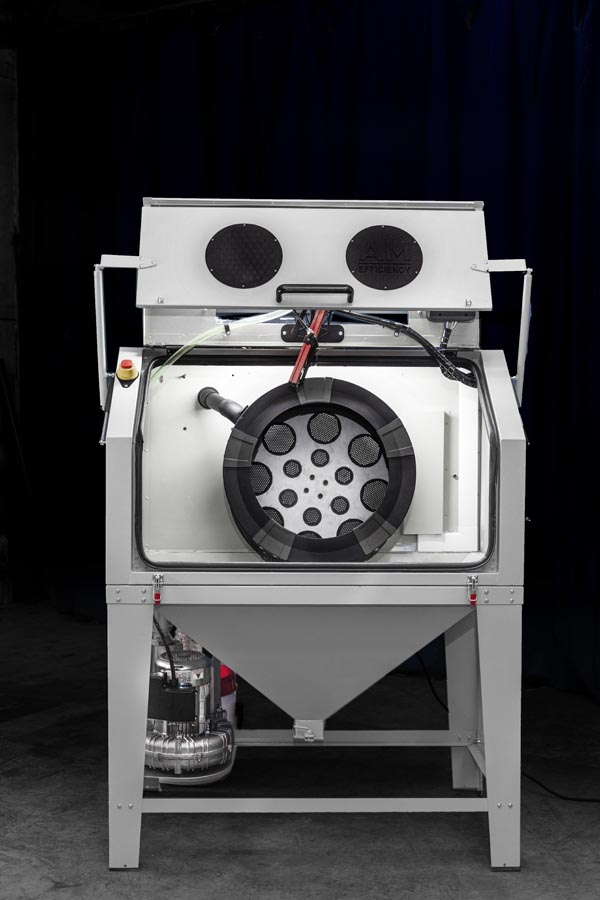

CCP-10

FROM AM Efficiency

CCP-10

Professional Post-processing

CCP-10 – The Simple Choice for Automated Post-Processing for 3D Printing

Take your 3D printing post-processing to the next level with CCP-10, the state-of-the-art automated finishing machine engineered for efficiency, sustainability, and cost-effectiveness. Whether you are a growing business or a large-scale manufacturer, this solution delivers consistent, high-quality results with minimal effort.

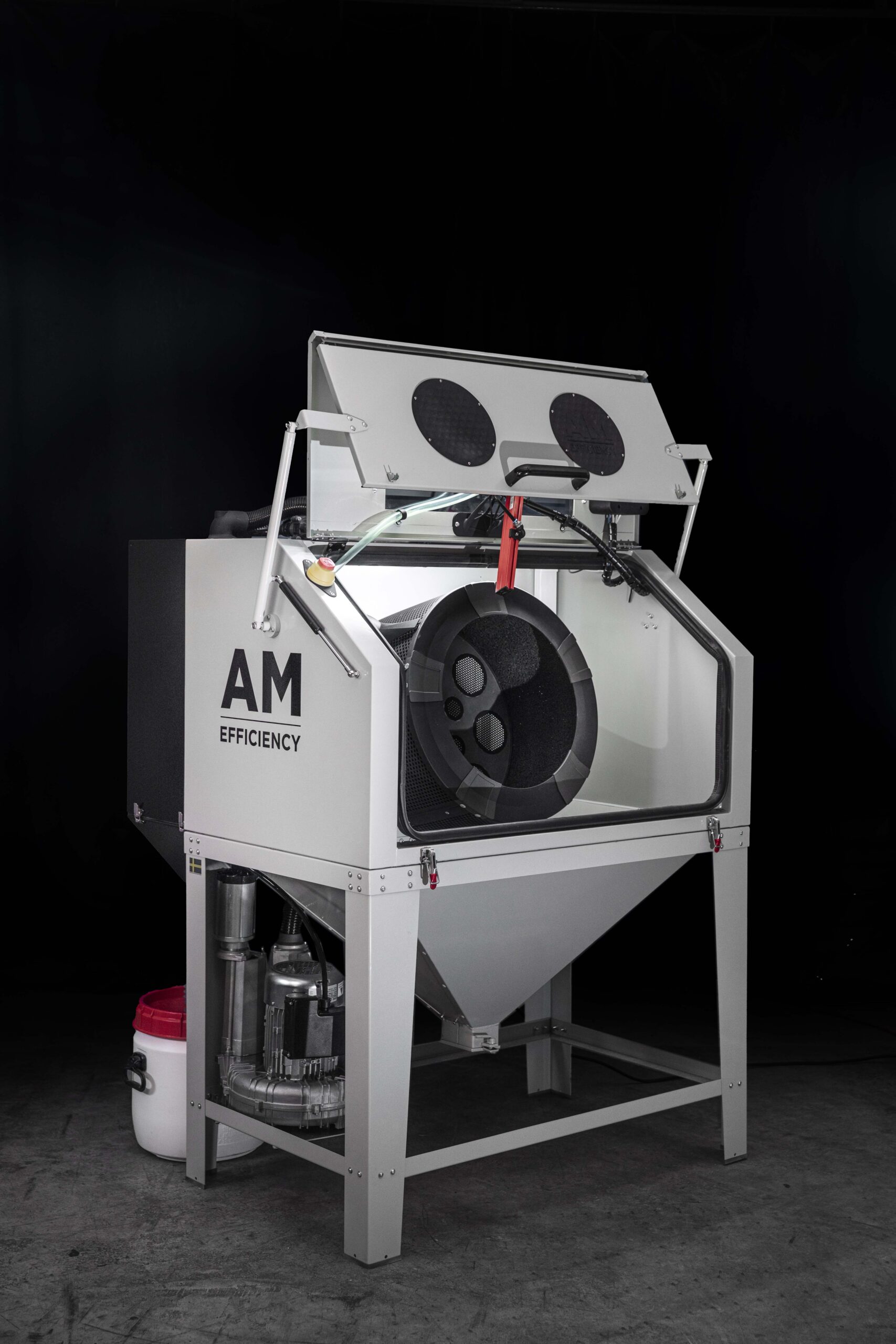

Compact & Space-Saving Design

Designed with a small footprint, CCP-10 is a perfect alternative to larger industrial solutions. It saves valuable workspace while maintaining top-tier performance. Thanks to its sleek and ergonomic design, it fits easily into tight spaces and can be maneuvered through narrow doorways for seamless integration into any production environment.

Versatile Post-Processing Capabilities

Equipped with possibilities for interchangeable media and customizable process settings, CCP-10 supports three essential post-processing modes:

- Cleaning – Effectively removes excess powder and dust

- Cleaning & Coloring – Simultaneous cleaning and dyeing for a uniform, professional finish

- Polishing – Achieves a smooth, refined surface for end-use applications

For businesses with high throughput and diverse post-processing needs, multiple units can be deployed to streamline workflows and maximize productivity.

Optimized for SLS, MJF & SAF Technologies

Specifically developed for efficient post-processing of 3D-printed parts, CCP-10 is fully compatible with SLS, MJF, and SAF printing technologies. It seamlessly handles parts from entry-level systems like Sintratec, Sinterit, and Formlabs, as well as high-end industrial machines from HP, EOS, Stratasys, 3D Systems, Farsoon, and other major manufacturers.

Eco-Friendly & Cost-Effective

Our solution is not only fast and reliable but also energy-efficient and environmentally responsible. The machine consumes less power and compressed air than traditional methods, reducing operational costs and lowering your carbon footprint.

Automated Precision – Minimal Manual Labor

With its fully automated workflow, CCP-10 eliminates the need for excessive manual intervention, allowing you to save time, reduce labor costs, and enhance production efficiency. The machine processes batches of parts in record time, making it an ideal solution for businesses looking to scale their operations with efficiency, sustainability, and profitability.

Fast and Efficient

- Fast ROI – lower investment

- Sustainable – less energy

- Cost efficient – lower cost of energy

- Automatic filter cleaning – less work

- Touch display – super easy to use keep track of your usage

- Cabinet volume: 440 litre

- Drum size: Diameter 55cm, depth 30cm

- Size: 1000x1100x1500

- Weight: 170kg

- Power connection: 230v 16A

- Air pressure: minimum 5 bar, maximum 9 bar

- Air consumption: less than 300Liter per minute at 6 bar

- Sound level: 72 dB